Here at PPI, our passion is custom packaging solutions that protect and enhance your brand. We know that all businesses and brands are unique – so there is no one size fits all solution. We offer multiple package printing methods – lithographic, digital and flexographic – to ensure we have a solution for every design, shape, size, quantity and budget.

Lithographic Printing/Laminating

Fondly known as “litho” in the printing world, the lithographic printing and laminating technique is one of the most popular methods for packaging production. This method prints the product packaging design onto paper stock via a custom printing plates, this paper is then glued/laminated to the cardboard or corrugated board used in the packaging. The benefit of printing onto paper stock rather than directly onto cardboard is the opportunity for extra details and customisation – such as foil stamping, embossing, or different finishes like matte or gloss. Lithographic printing is high-quality and allows crisp, photo-realistic printing to bring your packaging to life. It’s also a cost-effective choice for high volume-printing for industries like retail, food, cosmetics, and electronics.

Digital Printing

Digital printing for product packaging is an increasingly popular technique, with the printer used bearing similarities to a printer you might have at home. The packaging design is printed directly onto cardboard or corrugated board substrate from a digital file, which means set up and turnaround times may be quicker than other more traditional printing methods. The digital format also allows for easy-to-update changes to the design, along with customisation options if you are dealing with multiple SKUs. Although there are fewer finishes (like gloss or matte) available with this method, digital printing is a great economical solution for short-run, low-volume packaging.

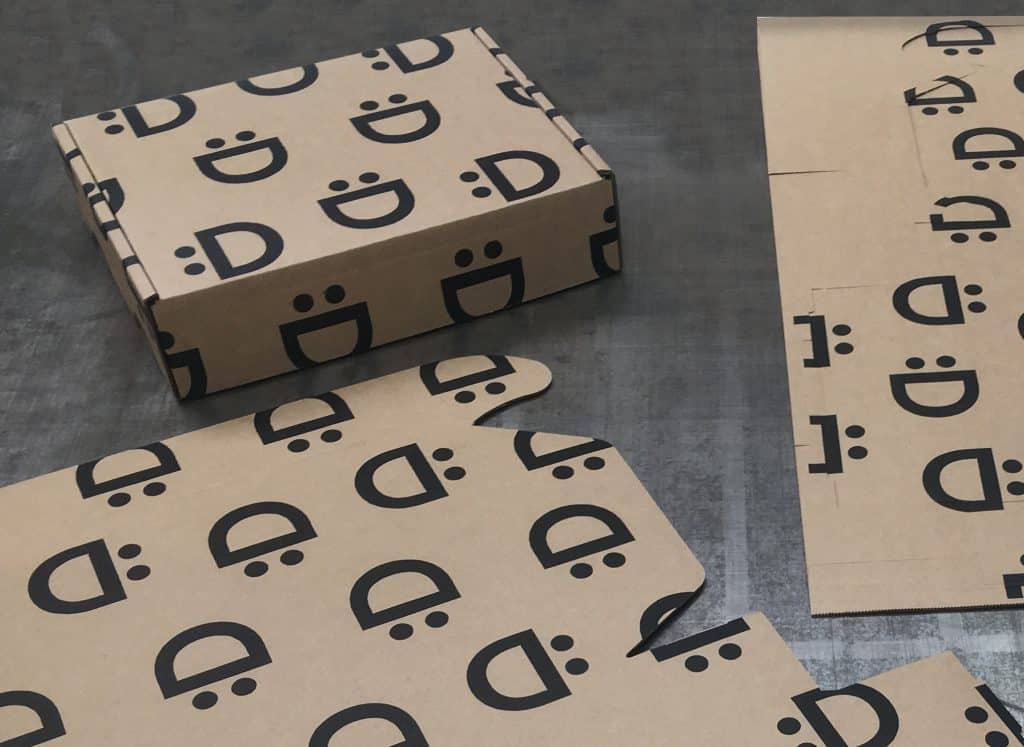

Flexographic Printing

Flexographic printing (known as “flexo”) is a tried-and-tested method of creating custom printed packaging that has maintained popularity for decades. Here at Production Packaging Innovations, we flexo print directly onto the packaging’s corrugated cardboard substrate, using flexible rubber plates wrapped around a cylinder to transfer the ink. You may have seen newspapers being printed using this technique! Flexographic printing remains a popular choice because it is an economic way of branding and its suitability to high volumes, making it a great option for printing on shipper boxes and primary retail packaging. While litho may be better suited to highly detailed designs – flexo offers a high-quality solution for efficient large-batch printing.

Our team of experts will work in partnership with you to not only choose the most appropriate printing method for you, but also to engineer your ideal packaging solution from start to finish. Our design, engineering and manufacturing team guide you through the process towards achieving your ultimate packaging outcome, via our family of state-of-the-art print machines. Connect with us or call us on 1800 25 8000 to book your FREE initial packaging consultation.

Recent case studies

Article

5 Reasons Why Bespoke Product Packaging is Important

In the era where consumers are increasingly transitioning to online shopping, product packaging and the unboxing experience it creates for a customer ...

More

Article

Packaging Design Considerations for Heavy, Bulky & Oversized Items

Here at Production Packaging Innovations, there’s no packaging job too big, too small, too heavy, too bulky or way too oversized. When packagi...

More

Article

What To Consider For Your Next Trade/Sample Kit?

A trade/sample kit is how businesses, especially manufacturers showcase their products for quality checks and industry feedback to potential clients. ...

More